25 Long Years Of Manufacturing Excellence With Quality At It's Best!

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Proin gravida nibh vel velit auctor aliquet. Aenean sollicitudin, lorem quis bibendum auctor, nisi elit consequat ipsum.

Sed non mauris vitae erat consequat auctor eu in elit. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Mauris in erat justo.

We are the industry heads and produce the most reliable and trendy solution you are looking for.

Cooking & Drying

Pressing

Odour Control

The place where you’ll get the effective solution for all your industry needs.

Industries We Serve!

Poultry rendering is a crucial process in the sustainable management of poultry by-products.The inedible parts of poultry, such as feathers, bones, and offal are converted into valuable products like protein meals and fats. This not only reduces waste but also provides essential ingredients for industries such as agriculture, pet food, and biofuels.

Red meat rendering is the process of converting inedible parts of red meat animals, such as cattle, pigs, and sheep, into useful products. This includes turning by-products like bones, fat, and offal into valuable materials such as tallow, meat and bone meal, and other protein-rich ingredients.

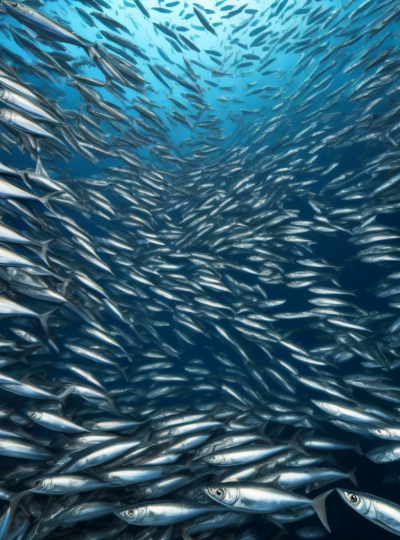

Fish rendering plants are specialized industrial facilities dedicated to transforming fish waste into valuable products like fish oil, fish meal, and fish solubles. This process involves the application of heat and pressure to extract oil and proteins from fish waste, which are then utilized in diverse industries such as animal feed, fertilizers, and biofuel production. The primary role of a fish processing plant is to convert fish waste, including heads, tails, and remnants from filleting and processing operations, into usable materials.

Wet Rendering

Wet rendering is a process where the tallow is separated from the solids while the material is still wet.

In this raw material rendering process, the material is usually cut up into small pieces before being cooked through a reactor so that heat transfer gets to the centre of each particle as quickly as possible. Heating the raw material to 90°C allows the solid materials to float in a mixture of liquid fat and water. From this point on, in the animal rendering process, the solids can be separated from the water/tallow by pressing (twin screw press) OR centrifuging with the water and tallow combined called the liquid phase. The solids are dried to produce meat meal and the liquid becomes known as tallow and sticks water where separators (polishers) separate the tallow and water.

Dry Rendering

There are two types of dry rendering processes known as batch cooking (cooked in batches) and continuous cooking (product is fed in and discharged continuously).

In this raw material rendering process, heating the material beyond 100°C basically means evaporating the moisture from raw material to a point where the solids start frying in fat instead of boiling in water. As the water evaporates, the temperature of the material (crax) rises to a point where discharge screening separates the crax material from the free-flowing liquid tallow. The crax material is pressed to produce a dry cake (meat meal) with the pressed tallow combined with cooker discharge tallow being further refined through centrifuging and polishing.

This animal rendering process is called dry rendering because the tallow and solids stay in contact with each other until the crax material is squeezed (dried).